Lean and/or chain cooperation?

You see it regularly on the websites of healthcare institutions: lean and chain collaboration. Companies are working on it because they want to serve customers better. What is the difference between lean and chain cooperation?

In any case, the great similarity is that, without being intrinsic to it, it is just a facade. The word efficient is replaced by the word lean. It has become a eroded concept, flattened into stickers in a planning session. For those who know lean and want to improve performance with the chain, this is one of the reasons why they prefer to do this under the heading of chain cooperation.

Same goal

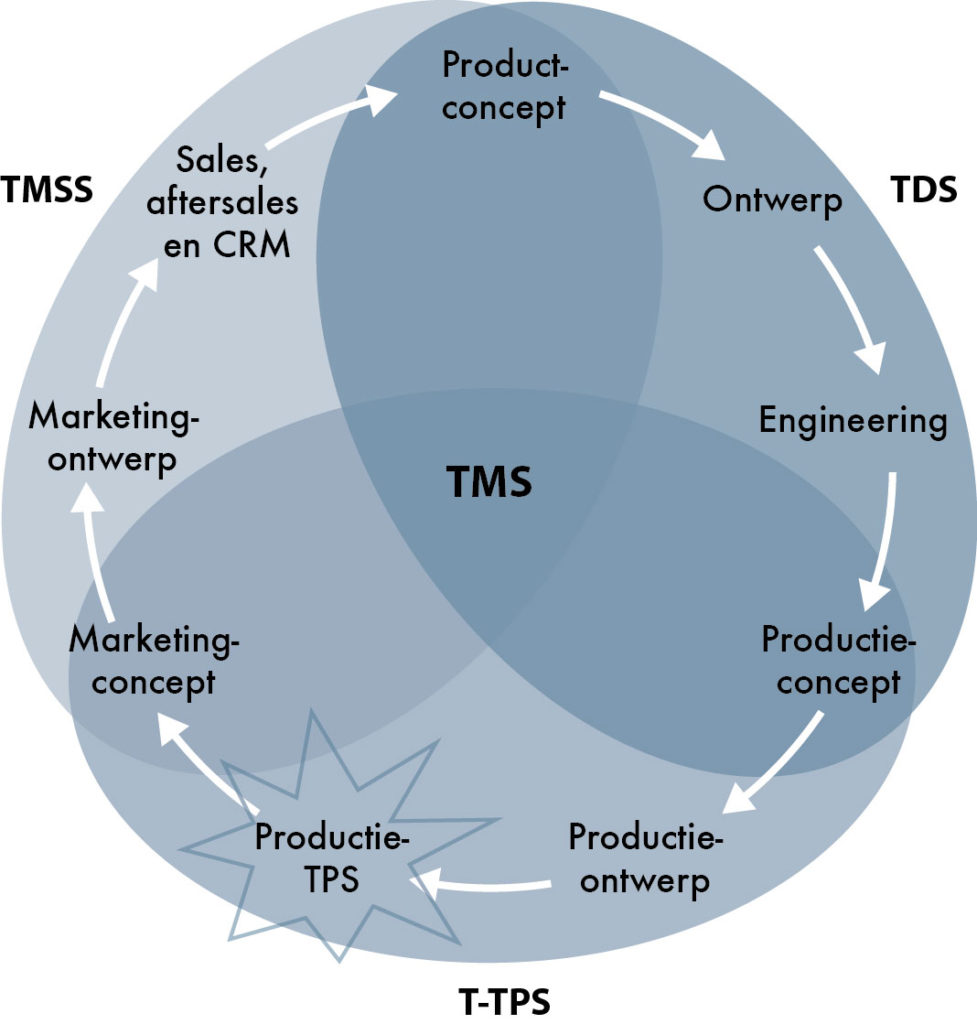

Let’s assume that lean and/or chain cooperation is chosen based on the need to perform better, for the customer and therefore ultimately for ourselves. So both forms have the same purpose. Now it seems the way we do it is different. With lean we remove waste from processes (efficiently) and with chain cooperation we try to find the right solution for the customer (effectively). At least that’s the picture. However, lean includes both the manufacturing and design side; an effective and smart design is needed to be made quickly and well.

Figure: Lean production (T-TPS) starts with a well thought-out design (TDS).

Influence chain

For organisations that work with lean, it is logical to start changing themselves and reflect on that. Everyone can do this for themselves, from their own intrinsic motivation. There comes a time when we notice that it is mainly at the intersection of knowledge that things go wrong. The biggest noise is on the interaction between parties (as in a whisper game). In addition, our own influence is limited when we are only one link in the customer’s process. We can improve, but the effect remains very limited when we are the only one in the chain. Successful chain collaboration does a lot for customer satisfaction (2), very much for employee satisfaction (3) and very much for the contribution in the network (3), but not every attempt at chain collaboration is a success. Exact figures are missing, but the assumption is that in half of the cases it stops somewhere.

Lean = chain cooperation+

The pillars within the lean principles (respect for people and permanent improvement) already indicate that this is not possible without the chain. After all, ‘if we want to respect others, do everything we can to understand each other, take responsibility and do our best to build mutual trust’, this automatically means that we have to work together with the rest of the chain. This requires such intensive cooperation that we are going to talk about chain integration, or even better: a network of partners; parties that fit together (purpose) and enter into long-term relationships, so that they can learn and grow together in a knowledge-sharing network.